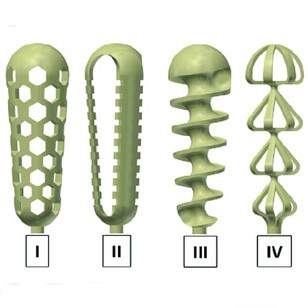

The FAMES Lab examined multiple designs for swab heads.

A fundamental truth throughout human history is that crisis creates innovation.

The COVID-19 pandemic has impacted just about every aspect of life, and it has required public and private entities to rethink the way they approach their work. That’s the comfort zone of researchers at the Luddy School of Informatics, Computing, and Engineering’s Fibers and Additive Manufacturing Enabled Systems Lab.

In a paper published by the journal Advanced Engineering Materials, researchers from the FAMES Lab studied the designs of nasopharyngeal swabs that could be 3D printed to efficiently address a break in the global supply chain while also improving sample retention performance when compared to conventional flock-head swabs. Conventional swabs, which are used to conduct COVID-19 tests, have suffered from supply issues due to their worldwide demand. Formlabs, a Massachusetts-based company that produces 3D printers, headed up the effort to fabricate a swab that works and clear it through the Food and Drug Administration approval process to fill the gap.

“They didn’t dwell on performance optimization,” said Alexander Gumennik, an assistant professor of intelligent systems engineering at the Luddy School and the director of the FAMES Lab. “They just wanted a minimal viable product. We saw an opportunity to dwell on optimizing the 3D-printed swab to performance (sample collection and retention) and patient comfort (dimensions, geometry, and “scratchiness” of the swab head). In our paper, we search for a design that optimizes performance. We started from those that Formlabs designed and other open-source designs, and then optimized them. We also created our own designs based on some deeper mechanical and fluidic considerations of the swab and the mucus-sample behavior.”

The search for an optimized, innovative swab may seem like extremely niche research, but it’s actually part of a larger view of how the world can prepare for future calamities.

“This isn’t just about the engineering of swabs,” Gumennik said, “but rather the approach to supply chain management in preparation of catastrophes. Right now, preparation focuses on what is called Gantt-chart or ‘Waterfall’ management. You try to plan and stock everything you will need in advance. But it’s a task that is impossible because you can’t predict what kind of pandemic will be coming next, so you can’t fully anticipate the supplies.”

Gumennik suggests that management should be approached with more agility akin to what is done by modern software companies.

“When there are breaks in the supply chain, modern, automated fabrication approaches, such as various forms of rapid prototyping, need to be applied to create—in a reactive, rather than planned—manner to provide a minimal viable product, which is then gradually optimized,” Gumennik said. “What happened with 3D printed swabs is an example of reactive, agile repair of a broken supply chain that was successfully implemented for the first time in history.”

The COVID crisis provided the catalyst for creating swabs that will be more comfortable and effective in the future by maximizing pore geometry to collect and retain a better sample while also designing the shape of the head of the swab to have fewer “spikes” that might scratch the nasal cavity. The FAMES Lab created an artificial nasal cavity for testing purposes, and the research sets a path for the resilient supply of widespread, sterile testing equipment as a rapid response to the current and future pandemics.

The results of the FAMES Lab’s research are provided as an open-source resource for other researchers, as is the novel design of the artificial mucus developed a spart of the research that can be used in future applications.

“The mission of our school is to use technology to solve real-world problems,” said Dennis Groth, interim dean of the Luddy School. “This research is the perfect example of using innovation to change the way we approach challenges, and it shows how our world-class faculty are making an important impact in novel ways.”